A flexible and responsive environment to the changes in processes can lead to the efficient implementation of the projects. Whenever an inefficient or faulty process is eliminated, the employee approach and work practices need to be changed. Hence, specialized knowledge and training are required to lower project failure risks and ensure optimal performance of the processes. The team needs to achieve proficiency in the methodologies and principles applied. Involve stakeholdersĪ structured process should be adopted where all stakeholders collaborate and contribute to finding solutions to complex issues. Eliminating the outliers and defects removes the bottlenecks in a given process. If the value chain is unable to reveal the problem area, various tools are used to find out the problem areas and outliers.

Eliminate any activity in the given process that does not contribute to the customer value.

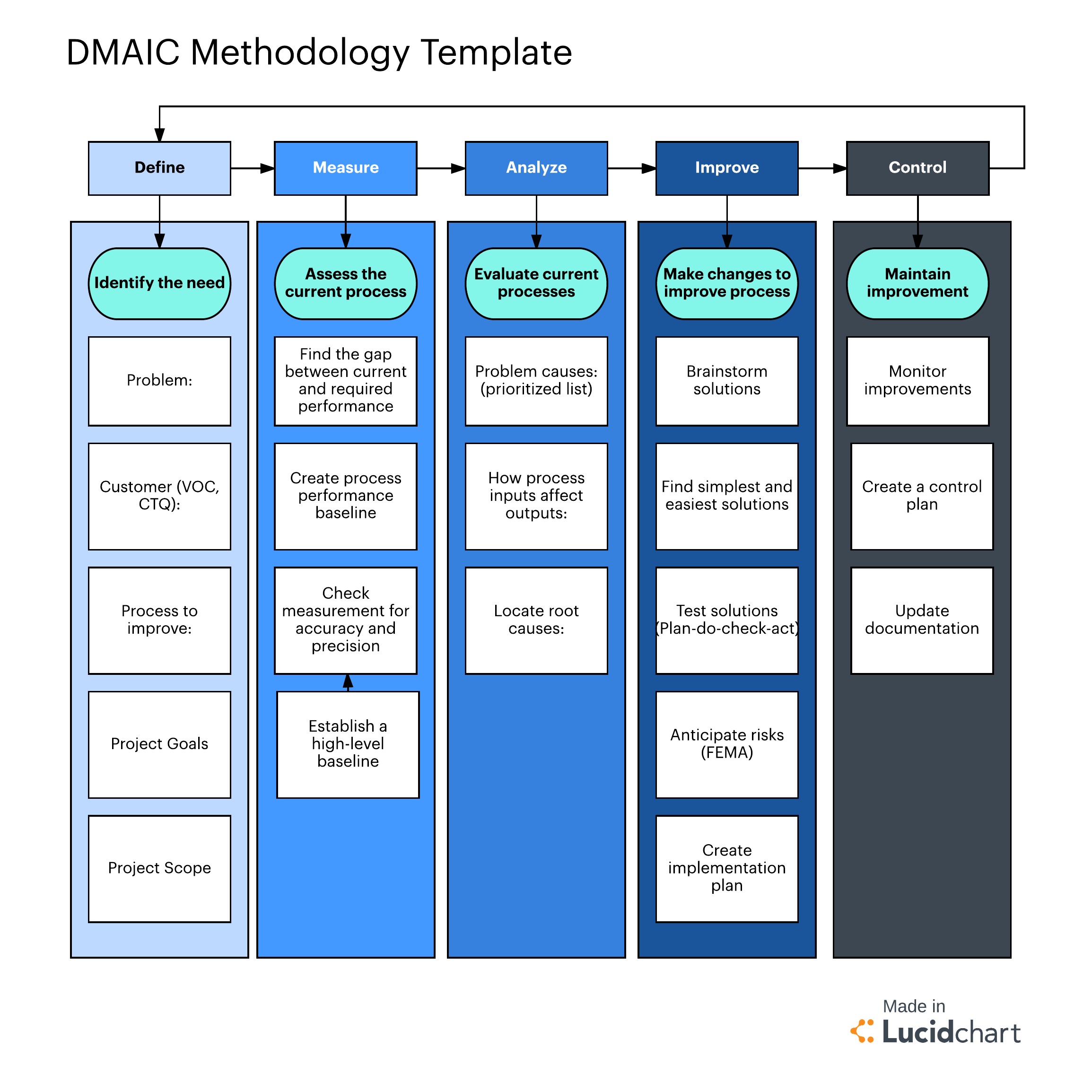

Eliminate defects and outliersĪfter the identification of the problem, make appropriate modifications in the process to eliminate defects. Verify that the data is assisting in achieving the objectives, whether more information is needed to be collected, or if data cleansing is required. Define goals for data collection, purposes for data gathering, and expected insights. Outline the steps of a process to find out unwanted areas and gather related data. Assess the value chain and find the problem It requires establishing quality standards according to the market or customer demands.

#Six sigma processes drivers

Hence, a business must understand the needs of their customers and the drivers of sales. The main objective is to maximize the benefits for customers. There are five main principles of Six Sigma: 1.

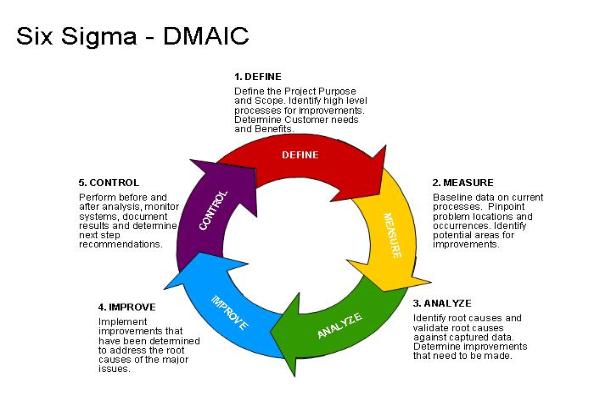

When a process produces less than 3.4 defects for one million chances, it is considered efficient. The failure of a business process or product is regarded as a defect. Hence, a process with six sigmas will achieve an extremely low defect rate. The term “Six Sigma” is derived from the bell curve in statistics, in which sigma represents the standard deviation from the center. It provides methods to improve the efficiency of business structure and quality of processes, enhancing the profitability of the business. Six Sigma can be applied to any process in any industry to establish a management system for identifying errors and eliminating them. Thus, Six Sigma creates an environment of continuous process improvement, enabling businesses to provide better products and services to customers. It provides statistical tools to eliminate defects, identify the cause of the error, and reduce the possibilities of error. Six Sigma is a term used to define various techniques and management tools designed to make business processes more efficient and effective.

0 kommentar(er)

0 kommentar(er)